-

Content Count

2,844 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Blogs

Calendar

Posts posted by UrPeaceKeeper

-

-

Greetings from the "not dead yet" me!

I realize it has been ages since I last posted on Arnies but life changed and I was unable to airsoft with any regularity. I sold most of my guns but recently acquired something new, the KWA HK45.

I realize it has been ages since I last posted on Arnies but life changed and I was unable to airsoft with any regularity. I sold most of my guns but recently acquired something new, the KWA HK45.Why? Why would someone who hasn't been able to airsoft in so long decide to purchase another airsoft gun that he can't necessarily use? Well the reasoning is simple:

Work, or training, or both.

I have been given the privilege of becoming a Police Officer and our department issued side arm is the venerable HK45. While I could bore you with the details on the original gun, I think anyone with access to Google can find out plenty enough. Suffice to say, the HK45 is meant to be a sharper USP. I bought the KWA HK45 to give me something to plink around with and maintain muscle memory. Of course KWA was kind enough to make this gun available so I could purchase it for just that reason! Thanks KWA!

I've been out of the game long enough to not really feel comfortable diving into the nitty gritty performance details but I will do my best to give an external overview.

The box, it's generic, and gets tot he point. Who cares anyway, I just want what is inside!

Step 02, open the box:

The box contains:

1x KWA HK45

1x KWA HK45 magazine

1x bag of unknown quality BB's (tossing in the trash)

1x HK trigger lock tool

1x KWA hop up adjuster arm

1x Medium backstrap

1x Baggie containing the manual (in multiple languages!) and Umarex registration card

Taking it out of the box the first thing you notice is the plastic used by KWA is very close in texture and feel to the real HK45. Obviously there are some differences as KWA is offering this at a fraction of the cost of the real thing. All things considered, I'm pleased how close it actually is. The stippling on the grip is smoother than the real HK45 which is more like holding onto skateboard tape than it is a plastic framed handgun. The plastic itself is shinier than the real one, but not shiny enough to look or feel fake or cheap and chintzy. Aside from the hideous orange tip (looks to be removable with a large enough hex key), the details on the KWA are pretty good. Certain things are accurately represented, such as the O-ring supported barrel. I think the Gen 1 HK45's came with a green O-ring on the barrel but mine has a black one. Not that it matters that much.

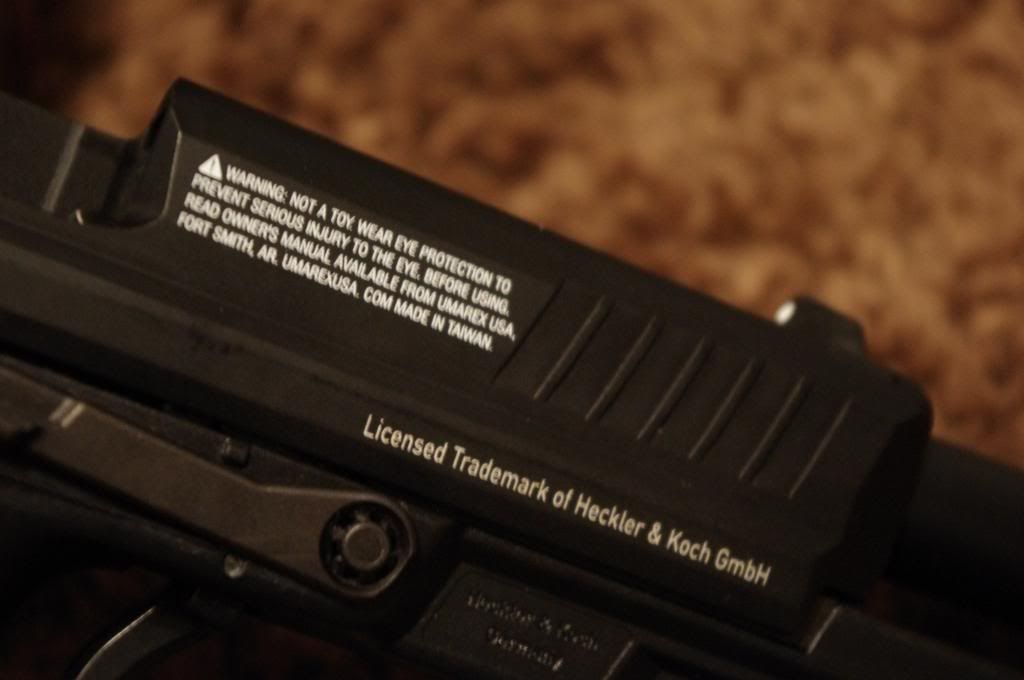

The trademarks are what I'd call the typical "Umarex" affair in that they are bright, and copious. I understand that there are some legal issues with trademarks but did we really need the giant WARNING NOT A TOY on the side? Seriously who thought these were toys? The Licensed Trademark of H&K GmbH is kind of annoying as well. Some of the import stamps are missing on the left hand side and others added to the right hand side. In general, because this is a training device and not an implement of anything else, I'll overlook these "added visual features".

Here is what they look like on the real one:

Side by side:

The keen observer will note that the KWA replicates the standard trigger unit for the HK45 while my HK45 has the "Law Enforcement Modification" (LEM) trigger on it. The LEM unit is quite nice and I have to admit, coming from the Springfield XD45 Tactical and the Beretta M92A1 to the HK45, I was a bit skeptical of the LEM trigger at first because it's technically a double action only trigger. Having put more than a few hundred rounds down range it is REALLY nice and shoots exactly like the XD45 Tactical does in pull weight but it breaks like my M92A1's trigger does which brakes like glass. One thing the LEM units do NOT have is the ability to decock the gun, nor do they have the safety.

The KWA DOES and the trigger unit operates differently as a result. While it is no surprise that an airsoft gun's trigger is light in pull weight, it is a bit frustrating. The KWA still has a reasonably distinct area in which a shot will break free, but there is no solid "stop" like there is on the LEM trigger where you can pull to and then break the shot when ready. The reset on the KWA is extremely vague as well where on the real firearm it is quite loud and distinct. I'm not sure if that will "wear in" or if there is a cure for it or not, but it certainly is a bit of a "detractor" from a training standpoint. The different trigger assembly produces a significantly lighter trigger pull. This is expected in an airsoft gun but I want to add that the real HK45's double action pull with the LEM trigger unit, is extremely heavy. Heavier than the M92A1's double action pull and just as long.

KWA on the left, real on the right

One other feature that isn't replicated are the night sights. I'm not sure if the TruDot sights are standard on the LEM HK45's or not but it would have been nice to have them on my KWA as well. I'm aware of the cost associated with proper night sights, but an attempt to make them glow in the dark is a step in the right direction.

On weight, the real HK45 is no lightweight kick boxer, it's a brute and quite heavy for a poly framed gun. The KWA is noticeably lighter and the balance is noticeably rear heavy. The real HK45 is more evenly distributed with the 10 round magazine and 1 in the chamber. This is to be expected as KWA has opted for a light weight slide, relatively soft recoil spring and a plastic barrel. Certainly not a huuuuge deal but one to point out for the hardcore enthusiasts.

Back to the KWA, the build quality is pretty good. It has been a while since I have used an airsoft gun but in general things are pretty tight. The slide does not wobble, much, on the frame rails and the parts seem put together reasonably well. I'm not expecting HK quality from a $156 airsoft gun and for what I paid, I'm reasonably impressed.

One interesting thing to note is that the slide from the real HK45 will go on the KWA frame but you can't get the slide catch back in due to the difference in barrel cut. The KWA slide will NOT go on a real HK45 frame. The magazines are also different in size and shape. A real HK45 mag is too long for the magazine well and the KWA magazines are too wide for the HK magazine well. Good news on that front, no chance of mixing up the parts!

That said, the magazines feel heavier than the gun itself. I'm not sure how I feel about the thinner magazine plate, but it is thinner. The markings on the magazine are very basic. It has the round count indicators on it but they obviously don't function and it has the stamped interlocking metal portion that the real magazine has. It also says "MANUFACTURED IN TAIWAN" instead of "MADE IN GERMANY". Small point to overlook!

I would comment on how the KWA shoots but sadly I have not shot it yet. I will try and do that tomorrow if I can. From what I can tell by the hop up unit, it should be a reasonably accurate handgun with the KWA hop up rubber being a split nub. How accurate has yet to be seen. AirsoftGI says my gun chronoed at 335 before leaving California. Since I'm not intending to use this gun for anything but training, this is sufficient.

Before I recap, I do want to talk about holsters. This is something that was critical to me as the gun needed to fit in my duty holster. The goal is to develop that muscle memory further without putting the wear and tear on my real HK45 and my wallet (.45 ACP is expensive!!). The good news is that it does indeed fit in my Safariland holster however I can't get the trigger strap to latch. I managed to get it latched once but was unable to get the over the top strap to latch. I compared the profiles of the two guns and they are identical, as are the lengths and angles of the trigger guard so I'm not sure why it wont holster fully. My Safariland is still relatively new so it may loosen up some still and eventually work. My holster is a Safariland 070-91 (Safariland says it fits the USP40 and USP9) and is the issued level III holster.

Alright, lets recap!

Pros:

+Quality polymer frame

+Easier on the wallet

+Minor details present (O-ring supported barrel, HK trigger lock, disassembly and backstraps, loaded chamber indicator)

+Less than a real HK45

Cons:

-Vague trigger unit

-Lighter weight than the real thing and rearward weight bias

-Fits in holster but can't be strapped in around the trigger guard

-No night sights

-GIANT ORANGE MUZZLE (I hate US import/Toy rules!)

Neutral:

~Trades (meh)

~No LEM trigger!!

Gun Prons:

I'll try and get a shooting report some time tomorrow. If you have an questions, feel free to ask!

-

2

2

-

-

Nice rifle....totally agree on the UBR deal. It's been turning me away from it because it can't use ASAP plate...

It wouldn't be the end of the world if it came with a sling attachment mount... Then I could actually use a sling, but as it stands, it does not, so you get the privilege of buying one of those TOO!

-

Well I've got a RS buffer tube here (no idea of brand unfortunately) and that fits my WOCs so I'd guess that's confirmed I'd say.

It's a shame about the ASAP with the UBR that's for sure, but still good looking weapon mate. Always good to see someone else going OD and definitely gonna have to do a longer weapon myself next time.

No Kidding? That would probably fix all of my issues with smooth cycling. Then again, this UBR's buffer tube is wider than that of the 6 position I had earlier so it moves smoothly, even more smoothly with the G&P bolt carrier

I need to get my Prime WA Length Steel BC shaved down about another tenth of a millimeter or two tenths and see if it helps with cycling (it should) because it was binding in the G&P 6 position.

I need to get my Prime WA Length Steel BC shaved down about another tenth of a millimeter or two tenths and see if it helps with cycling (it should) because it was binding in the G&P 6 position. -

Niiiice.

What kind of UBR mate? I know RS stocks fit WOCs, but I'm yet to be able to find out what kind of thread PTS used on their UBR.

It's the PTS one for the WA/G&P. I'm not sure if RS stocks fit WOCs. I don't have one on hand to try out although I could have asked my buddy for his VLTOR MOD stock and buffer tube before he leaves for Texas. That is a bit involving as the UBR is not as simple to just remove as an M16 stock is or the 6 position is.

I only have one complaint... Magpul's Best stock is 100% incompatible with their own, best sling plate... the ASAP plate wont work because they have the other sling attachment points, which conveniently enough, none came with the UBR stock... I wish it would have come with just one, that would have been plenty.

Anywho...

Better Photos

-

Teaser Shot before better pictures tomorrow:

-

More Pics of the WOC before it receives a bit of a tweak externally.

State in picture:

Internals:

Prime Steel Bolt Carrier (Sanded, a lot, to get it to work better)

RA-Tech Aluminum Nozzle with NPAS

RA-Tech Hop Up rubber

JDT 6.03 509mm length tightbore

AABB Hardy Recoil Spring

G&P Steel Buffer Lock

DPMS Modified Charging Handle

All other internals are stock WOC internals

Externals:

Dboys M5 RIS

G&P FN M16A4 Metal body (newest version, still wobbles a little bit)

G&P 6 position Buffer tube with G&P Crane Stock

ERGO Grip vertical Grip

PRO&T AN/PEQ 15 w/ Green Laser

ACM 4x32 TA31 ECOS ACOG

JG BUIS

MAGPUL ASAP plate

Dboys Bipod Adapter with Rockford Mount Harris style bipod

I have 7 magazines converted to HPA. When the mags don't leak they are pressurized to 140 PSI, NPAS will be set (I haven't had much of an opportunity to tweak this yet) to around 400 FPS w/ .20's (Actually the equivalent Joules with .28's).

Changes coming soon:

Magpul UBR stock in OD (Not sure how I'll like OD, but nothing a rattle can can't fix

)

)Some Rail Covers for all that virgin rail space

-

Sorry if I missed it, but did these gears actually reduce the noise? Looking to build a DMR here soon and think these would be the best route. Good review!

Sorry for the delay (Oi, looks like I don't really jump into this section a whole lot) but I'm not sure if they reduced the noise so much as changed it's pitch. I wouldn't recommend double torques for a DMR though, too much torque and it can reduce the trigger lag with rather lackluster batteries. As for the overall quietness of the gun? It's pretty dang quiet. It certainly helps that there is a quarter inch of wood on either side of the gearbox

As to how these are holding up? Pretty dang well I might add. Well enough anyway, but like I said, an SP130 spring isn't exactly "testing" Others on Airsoft Mechanics are reporting gear shaft failures on their standard ratio and high speed ratio gears at spring rates higher than an M130 spring.

-

Currently it appears we are unable to set animated gifs as our avatars? I know this opens up it's potentials for abuse, but I know we had them on the old forums back (I believe it was Donut who had the image of the anime character getting stomped all the time?)

Anyway, I would kind of like them back so this:

can be my avatar

If thats possible? Or is there a good reason as to why it was removed? I'm not worried about overloading my founders photobucket account

If thats possible? Or is there a good reason as to why it was removed? I'm not worried about overloading my founders photobucket account

-

Some changes externally to the WOC.

5KU 6 Position Buffer Tube

Magpul ASAP

PRO&T AN/PEQ15 w/ Green Laser (PEW PEW FIRIN MAH LAZOR BEEMS!)

G&P Crane Stock

-

I'm good with 400+ with .25's at the moment... besides, at 12lbs of rifle, I would not want to mess with a rig too...

With RA-Tech NPAS though... more recoil FTW

Air rig isn't too heavy, but then again I'm used to hauling around a lot of gear including my G&G M14 Veteran, which weighs a lot.

-

So who's going to be the first person to tap their mags for HPA and crank up the PSI?

Ok

-

Personally, the only fair way to get the FPS of a GBB anything is to use the weight of BB you are going to use on the field. Anything else IS cheating the chrono. As someone else pointed out, just because your gun chrono's at 400 w/ .20's doesn't mean it chronos at 1.5J with .28's. Heck most AEG's dont even follow that rule, but that is besides the point. GBB's do not follow the same principles that AEG's do for FPS readings, because our gas expands, therefore, your muzzle energy (if your limit is 1.5J) needs to be the equivilant of 1.5J with whatever BB weight you are using, not of .20's. The reason that is fair is because my own WOC chronos at 455 w/ .28's and chronoes at 455 w/ .25's and about 445 w/ .20's.

The idea of using a BB Weight chart VS FPS is probably the smartest and best way to figure out acceptable FPS using certain BB weights.

At anyrate, whoever asked about when the M21 was being released, it IS released, remove the fire selector and you are done. The original M21 was just an accurized, semi auto, wood stocked M14 with an ART Scope on it. The modern M21 hasn't changed much from that but uses either the M1 or M3 scopes in it's place. The USMC DMR stock is used in conjunction with USMC Semi Auto only M14's, not M21's. Sorry, side tangent

Beautiful M14's guys, I can't wait to see what the first one does with an NPAS and an HPA rig

-

Also is this feature normal (bent butt plate)?:

http://i224.photobucket.com/albums/dd153/Johnnierkt/WE%20M14%20Rifle/IMG_2693.jpg

It's not bent like that accidently. Thats how the real one is, it's to facilitate shouldering with body armor on. If you fold it out and shoulder it, it helps with the weight a little bit. I personally consider it useless in every position but prone, but that bend is there intentionally.

-

1

1

-

-

Been toying around for a few months on and off regarding putting a small piston inside the nozzle. My point being that recoil gases used is too much for the WA system. Adding a piston inside the nozzle to push the BCG back would dramatically reduce the gas consumed on blowback.

Finally was able to do this with success, highest reading so far on .2 is 450 fps, can probably up the readings by using a stronger flute valve spring. I can also finish 30 rounds easily on one trigger pull! After 30 rounds there is still enough gas inside for another load of BBs.

Cool down is not as bad as stock setup since I do not need a lot of gas per shot. The only drawback is BCG does not cycle fully rearwards so no bolt lock function. Also recoil is quite tame comparatively.

How does the blow back feel? I also toyed around with steeling the NS2 style gas system and hijacking it for the WA system, but without access to a machine shop to make new bolt carriers and nozzles it was a dead end adventure. I still have the ideas rolling around in the head of mine, but I'm not sure how much it truly matters

I'm curious to see how you did it?

As for the Big Dragon (READ: ENERGY) High flow Valves, give them a miss.. the shafts on them are too long to cycle correctly with a 150% hammer spring in my WOC and WA mags, and the ones I cut down with the mill either runaway firing or double tap every time. Stock WA valves are fine, just need to find a source for good quality valves... How do the AGM valves compare to WA valves (Read: How does an AGM mag compare to the WA Mags in terms of felt blow back and FPS?)

-

More of the ho:

Now Working!

(Sadly mostly stock now)

Exteranls:

Dboys KAC M5 RIS

ErgoGrip Vert Grip

Dboys AN/PEQ2

ACM TA31 ACOG ECOS w/ Killflash

Rockford Mount Harris Bipod (Modified not to suck)

DPMS Charging Handle (Modified to work

)

)Internals:

Stock WOC Trigger Group (Yup, safe/semi/auto, the burst kit is just too finicky)

G&P NP Bolt Carrier

JDT 6.03 509mm Tightbore

AABB Hardy Recoil Spring

Mags:

4 WA Mags (One leaks from the main valve slightly)

3 Bomber Mags

Chronos a toasty 455 +/-10 FPS w/ G&G .28's. Next paycheck I'll pick up another G&P Bolt Carrier with NP and drop a 5kU NPAS in it (since I have two laying around...)

Plans: Semi Auto DMR platform using HPA rig, a steel bolt carrier (if I can get one of my two to work with the aluminum nozzle I have) and shooting about 390 w/ .28's That'd be ideal

-

Hi. What is it doing; does it occasionally shooting semi only, two round burst, etc.?

Sending PM to keep from going OT

-

The G&P M16A4 WOC in final form. Only change may be the addition of a Specter 3 point sling, but nothing major. Internally it functions, finally, and I have another bolt carrier on the way which should hopefully also produce fun results

Still can't get the burst to work correctly all the time, not sure as to why either, but ohh well!

-

It has some cheap design features that will be a point of failure. The recoil buffer is held in by a little detente, point of failure in the making.

http://farm5.static.flickr.com/4073/4770697143_346fc52050_b.jpg

I dont mean to point out the ignorance in this post, but this is how real AR buffers are held in, just an FYI. I'm not sure if you realized that or not. The Buffer detent only takes the pressure of the buffer when the receiver is opened, otherwise the bolt carrier should push the buffer back such that it never makes contact witht he detent. That is by design, and if it's worked for the 40 years the M16 has been in service, I'd say it's safe... unless of course you where talking about the materials used...

I'm not surprised that the VFC is a bit meh. VFC was DUMB to stray away from the WA platform without vastly improving on it. They sank their own adventure into GBB's just by doing that... I hope it performs well though, for your sake!

And I'm still not a fan of VFC's AEG internals either...

-

The G&P M16A4 WOC

Still has not been used in the field by me, but she is upgraded-ish:

G&P Burst Trigger Kit

G&P Anti Rotation Links

JDT 6.03 509mm Tightbore

AABB "Hardy" buffer spring

Everything else is Stock G&P WOC

BCG #1:

Element Steel Bolt Carrier (Small Weight Reduction)

AABB Plastic Nozzle with Aluminum Tip

5KU NPAS

-Still doesn't work

BCG #2:

AABB Bolt Carrier

AABB Plastic Nozzle with Aluminum Tip

-Positive Pressure system using G&P's stock nozzle components, it cycles, better than the NPAS does.

Externals:

Dboys M5 Rail Unit

ACM TA31

ACM KillFlash

Ergo-Grip Vert Grip

-

This seems like the logical place to ask a question like this (with the high probability of running into someone who has used this part), but has anyone used the Big Dragon High Flow Valves for their magazines yet? I'm looking to replace some Bomber Main Valves in two of my mags (one with a chronic leak) and if they are worth a hoot to replace all of the valves in my magazines with the same. Replacing with the same, and supposedly highly available valves would be nice for consistency's sake, but I dont want to take the leap of faith and buy 7 of these just to get bit and have worse performance than the stock WA valves in 3 of my magazines in the 2 bombers in my other two mags and the 2 stock valves in the 2 KA mags I plan on buying as well. Especially with a steel bolt carrier that I can barely get 30 shots out of anyway (Element bolt carrier will go under the milling machine to lighten up alot more!) Part of that may be the damaged blow back O-ring, but the main valves being a bit restrictive are not helping either in the 2 with bomber valves, which barely cycle for 15 rounds on propane before venting =(.

-

^I KNEW IT - the Ehobby pictures were WAY too similar for them to be different gears lol.

UPK, you know SVX personally? Cool...I bow before that guy

.

.I had a 16:1 set for my Recce rifle some time back, but the spur gear axle broke off

SVX was a team lead for me for a while, now he's just another grunt like myself out on the field, except he's toting his M60 and I'm toting my M14. I'm wishing he'd hurry up and get back from his Deployment though. The Airforce is taking their sweet time sending him back home!

But yes, SVX and I are friend

I have a whole bunch of his real gun stuff sitting at my house LOL.

I have a whole bunch of his real gun stuff sitting at my house LOL.And yes, the KA's are most definetly the same, although I wouldn't be surprised if the QC on the SHS's are a little higher. I've only had good luck with ONE KA part, and that was the hop up unit, and even then, others around me had the worst luck with theirs

I really enjoy the SHS gears, the trigger response is not horrible even though these gears are straight up overkil.

I really enjoy the SHS gears, the trigger response is not horrible even though these gears are straight up overkil.I did superglue the halves of the Sector gear as they where coming apart on the SP150. I'm thinking I should probably invest in some form of punch and key the halves together somehow, but I'm not sure how I'd go about doing that. For the cheap price I paid, I'm willing to do a little work

I'm sure the superglue will be more than sufficient... I hope

I'm sure the superglue will be more than sufficient... I hope

-

Rejoining the AR15 Herd after a long hiatus

It needs cleaning... bad...

G&P WOC... stock... for now... Got a killer deal on it, 450$ with 6 mags which only one worked. After taking apart all 6, I have 5 working mags with Propane and one completely frakked mag. So I have 4 WA mags that work and a Bomber mag, and a completely stock G&P WOC M16A4, for 450$

Thanks SADman, it was a deal I couldn't pass up. Now time to make it skirmish worthy!

Thanks SADman, it was a deal I couldn't pass up. Now time to make it skirmish worthy!

-

Purchase History:

This piston was purchased more or less out of frustration over the lack of information and the amount of MISinformation being spread about this piston. Over on AirsoftMechanics, the various techs where posturing and speculating, so I decided to end that speculation. My G&G M14 recently ate a Bravo Piston (More than likely due to my error, but thats beside the point

) so I decided to give this piston a try and see what G&G's Hype was all about.

) so I decided to give this piston a try and see what G&G's Hype was all about.What follows is my best attempt at an unbias review of a G&G product (for those that know me, that should be laughable

)

)This piston was ordered from Airsoft GI for the price of 45$ (Less after I combined it with some other items to get free shipping and used the discount code "tim" for 10% off)

Arrival:

Typical G&G packaging, a nice resealable baggy with the G&G Paper Tab over the top. (No pictures sorry). This is G&G standard packaging, and is about the same from other piston manufacturers. My Bravo didnt come in any real packaging, just some thin plastic.

The Piston:

As you can see, the piston is a dark flat grey. The texture on this piston is near super fine grit sandpaper in that it doesnt feel smooth like a Delrin or ABS piston and it's not textured like a Nylon piston is. It's not "rough" perse like I'm worried about sanding the piston rails in the gearbox, but it has that feeling like fine grit sand paper.

The piston itself failed the cut test, and by failed, I mean it wouldn't cut. You can see in the picture of the top, where I attempted to cut a sliver off. What does that mean? For this piston, I'm not entirely sure, for other pistons it's a test of hardness, and it's no brainer that this piston is probably pretty dang hard. Why? Check out the Redwolf "Stats" for this piston:

Specific Gravity: 1.153 (Specific Gravity is a fancy way of saying Relative Density or how dense is it compared to water, in this case, slightly more dense)

High Rockwell Hardness Rating: HRL 87.2

High Impact Strength: 57.3 KJ/m^2

Important Observations:

This piston is translucent!

Others have noted that the design of the piston may be it's ultimate flaw. Being based around the original TM pistons and not G&G's Reinforced or Prometheus or Azimuth's newer designs in which the piston rails are cut to reduce friction and the sides of the teeth are supported by plastic. I however remain skeptical of the problems associated with that. Then again, those others also build setups which are way out of the playable realm for 90% of airsofters.

Single Metal Tooth, to some thats a disadvantage as there is a higher probability of the tooth caving in, personally though, the high Rockwell harndess should keep that firmly in place but only time will tell.

The piston is also semi flexible. With some grunting I was able to slightly (and yes I mean slightly) deform the opening where the spring goes in, but the piston returns happily to shape.

Second tooth is removed to facilitate AoE adjustment, the third may need shaved down slightly.

Some slight sanding of the piston rails was necessary to prevent binding in the gearbox, but this has become normal for pistons I put in guns.

Overal Strength:

I wish I knew. So far this piston has cycled maybe 300 times since the failure of my Bravo Piston on the SHS gears. I have a Guarder SP150 coming to test this piston a little bit more thuroughly, but on an SP130 the 300ish cycles there isnt a sign of wear at all. Only time can truely tell if this piston will last or it will fail.

Performance:

I put everything together in my G&G M14 Gearbox:

G&P M160

Guarder SP130

SHS 100:200 Gears (See Review)

G&G Nano-Co Alloy Piston

SHS Pinion Gear

SW-AB Long

G&G Aluminum Piston Head (stock)

G&G M14 Veteran Cylinder and cylinder Head (stock)

G&G Air Seal Nozzle for M14/AUG (stock)

G&G Bearing Spring Guide (stock)

AoE Adjustment with Sorbo

and it survived 300 rounds with an SP130. Horribly stressfull (right

) and a long torture test.... Ok call me a liar. I honestly dont know what to say, it has survived the test bed so far, I await a new cutoff lever to give me my semi auto back and the Guarder SP150 before maknig a true final judgement.

) and a long torture test.... Ok call me a liar. I honestly dont know what to say, it has survived the test bed so far, I await a new cutoff lever to give me my semi auto back and the Guarder SP150 before maknig a true final judgement.Overal Ratings:

Build Quality: 10/10 It's a really nice piston. The material is incredibly fascinating.

Performance: ?/10 I'm going to leave this one as a ? mark. Being as the Piston's only job is going to be staying together, I can't judge the performance of this product yet. I have high hopes and confidence that this will survive M150 mayhem.

Price: 6/10 At 45$ it's expensive, especially when there are any number of other pistons out there that will probably provide the same performance for a lesser cost. On the other hand, I wont know if it's actually worth it untill it fails and what that round count is.

Overall: 8/10 If I had to put a number on it now. The price is a real downer, but the material has it's promises. Only time can really tell if it's ACTUALLY worth the price and if the performance is there or not.

-

Purchase History:

I purchased these gears on Ehobby Asia after a discussion about the quality of their other gearsets. After having seen SilentVectorX's 13:1 High Speed SHS gears in person, I set my heart on a set of cheap helicals with the thinking of "Why the heck not?" For 19$ whats to lose? If they are complete knaff, then I can toss them! After seeing that the only Helical gearsets they had where in 100:200 (Same ratio as Prometheus Double Torques) and 100:300 (Prommy Tripple Torques) I settled for the lesser because I was pairing it with a G&P M160 motor and only a Guarder SP130 spring.

Arrival:

The packaging they arive in is pretty plain. (Thanks Airsoft Park for the picture because I literally destroyed my packaging

)

)It gets the job done and protects the gears. No issues here.

The Gears:

It appears there are two things going on with these gears. The portions that are grey are Sintered powder steel like we are all used to from Systema gears or most stock gears, the black is all machined (Obviously some form of CNCing as cutting gears without it would be a PITA). The machining is high quality, for 19$ I wasn't expecting the worlds greatest machining, but this is dang nice, definetly on the order of magnitude I'd expect from a set of Prometheus gears.

[Please forgive semi blurry photos, my digital camera has worse ratings than my cell phone camera =\]

Bevel Gear:

Spur Gear:

Sector Gear:

All together again:

You can see the gears have been run through the "break in" process of about 5 minutes continuous run with just gears and motor in the gearbox. They have about 1000 shots on them with the SP130, all of that has been dry firing.

Important Observations:

SHS has done something which may or may not be a problem. The post for the tappet plate is about a hundreth of a mm out further and sits three tenths of a milimeter higher. The results? In my G&G M14 gearbox it rubbed like crazy so I had to take a dremel to the tappet plate guide to get it to spin freely in there. Shimming the gear higher would have not moved it far enough to prevent this contact from happening and would have had worse consequences for the rest of the gears.

The method SHS is using to attach the two halves of the Sector gear is through the use of Pins. Unfortunately on mine, the halves tend to seperate while under load. Not a huge issue as the next time I catch them apart I plan on super gluing the halves back together. Some form of better staking or keying like they did on their Spur gear and bevel gear would have been nice.

Six ARL stop points. Works for me!

Overal Strength:

I'm not 100% confident in the strength of these gears, only because I've not read any reports of people using the double torques (largely because the double torques only come in helicals which people want to avoid, except me

). However, I do know that the 13:1 ratio gears are not suited for M130 springs. There is some obvious logic going on here, but the reduction in teeth count to get the 13:1 ratio is giong to obviously sacrifice some strength and holding capability as there is simply less material there. As for these gears? I'm not sure, an M130, certainly. SHS's website (www.topaeg.com) rates the gears to an M180 for the 100:300 ratio, I can only imagine the same goes for these. Obviously with the come about of LiPo's for high current output and stupid high torque and high RPM motors you can under gear yourself a little bit as I'm sure the torque ratings are good for a stock TM motor.

). However, I do know that the 13:1 ratio gears are not suited for M130 springs. There is some obvious logic going on here, but the reduction in teeth count to get the 13:1 ratio is giong to obviously sacrifice some strength and holding capability as there is simply less material there. As for these gears? I'm not sure, an M130, certainly. SHS's website (www.topaeg.com) rates the gears to an M180 for the 100:300 ratio, I can only imagine the same goes for these. Obviously with the come about of LiPo's for high current output and stupid high torque and high RPM motors you can under gear yourself a little bit as I'm sure the torque ratings are good for a stock TM motor.Performance:

After running them through a break in I put everything together in my G&G M14 Gearbox:

G&P M160

Guarder SP130

SHS 100:200 Gears

G&G Nano-Co Alloy Piston (See review)

SHS Pinion Gear

SW-AB Long

G&G Aluminum Piston Head (stock)

G&G M14 Veteran Cylinder and cylinder Head (stock)

G&G Air Seal Nozzle for M14/AUG (stock)

G&G Bearing Spring Guide (stock)

AoE Adjustment with Sorbo

The ROF is about 22 RPS (that was a by ear comparison from other guns, I'll get audio tests later when I get my semi auto working again!) on a 9.6v 4000 mAh ELITE Celled battery pack. Not too shabby for a set of double torques which are entirely over gearing the gearbox just for the luls of having helicals

Overal:

Build Quality: 8/10 The issues with the tappet plate post and the halves of the sector gear coming apart lose 2 points from the overal build quality even though they are MINOR, they still require work on a gearbox to get them to work, and I see that as a disadvantage for those looking to just drop these in and go. The Tappet Plate post issue MAY NOT be a problem on a V2 gearbox or a V3 gearbox and may be related to the G&G M14 gearbox but regardless. The helical cutting is superb and overall the gear quality is great, the ARL positions are crazy!

Performance: 10/10 They work, and I'd say probably work well up to an SP150 spring. I will update in about a weeks time if they hold or not as I will torture test them with an SP150 spring!

Price: 9001/10 Yes, it's over 9000! For 19$ these gears are a STEEL (see what I did thar?) The price to quality ratio is simply outstanding, and I'm confident that if these go tits up, replacing them isn't going to make me wish I hadn't bought them. For 19$ there is very little reason not to buy them. Obviously I haven't really gotten them tested to any extremes (Sp130 =/= extreme)but I'm more than happy with the purchase.

Overall: 9/10 Cheap, quality gears, nothing really more to say about them!

Note: These gears have been rebranded by King Arms and the KA cost nearly double the price for the same product. There was another company that also purchased these gears and rebranded them as well (can't remember to save my life). These are the originals. SHS has come out with a number of cheap, yet quality products for AEG's. I look forward to making more purchases with them!

KWA HK45 Initial Impressions and Real Steel Comparison

in Pistols (Gas)

Posted

Sounds expensive for what I plan to do, I'll have to go looking to see what all was involved in doing so!